Structure types and characteristics of container bags

With the widespread use of container bags, various types of container bag structures have appeared. From the mainstream market, more users are willing to choose U-shaped, cylindrical, four-piece group, and one-handed. Structural type of container bag to meet its use requirements, today, let us share the manufacturing process and structural characteristics of these several types of bags.

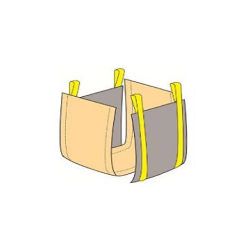

The first is the U-shaped bag. The bag body is composed of three pieces of base fabric, one U-shaped main body and two side panels. The U-shaped main body constitutes the two sides and bottom of the bag body, and the entire bag body is sewn through two U-shaped lines. To be done. The manufacturing limitations of the bag material of this structure are relatively small, and the equipment utilization rate is relatively flexible, which brings feasible production opportunities for some small batch orders. The popularity of the U-shaped bag in use is also due to the fact that it can maintain a good square shape after filling. The four-side seam of the main body effectively controls the lateral deformation. At the same time, the U-shaped bottom is connected to the main body as a whole piece of base cloth, which is beneficial to bear the pressure of the bottom of the bag when lifting, so some high-end dangerous bags also tend to choose the U-shaped structure.

The cylindrical bag is one of the most common types of container bags. It is a type of container bag made of a piece of cylindrical cloth as the bag body and is sewn with a round or square bottom cover; ordinary cylindrical bags, its seam The manufacturing process is relatively simple, but some users who have a harsh use environment and have certain risks in turnover handling operations will require the factory to add a belt, belt or sling bottom support technology to the bag design. In general, because the general cylindrical base fabric requires large equipment to produce, it is necessary to have a certain batch of orders to better reduce the processing cost.

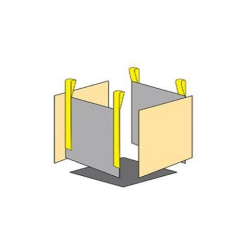

Four-piece FIBC, as the name suggests, is a type of FIBC with a basic bag body structure consisting of four main bodies and an independent bag bottom. Although its sewing process is relatively complicated, it is still favored by a large number of users. , Because it combines all the advantages of U-shaped and cylindrical bags, the bottom can be independently reinforced, which reduces the dragging of the bottom. In addition, it is convenient to use cross-angle slings, and the lifting force is uniform at eight points, so its shape during filling and transfer. The effect remains the best, and customers who pursue appearance and maximize container utilization are still sticking to their original choice.

Grab the container bag, it should be a relatively alternative type of container bag. Its bag body is generally made of cylindrical cloth material, and there is no sling in the usual sense. The sling is a whole piece of base cloth connected to the main body. It is stitched with lap joints, a bit like a convenience bag used in supermarkets. The bag of this structure has higher requirements on the quality of the base fabric. First, the base fabric is used to replace the sling, which itself has higher requirements on the strength of the base fabric. Secondly, this kind of bag is not suitable for stacking storage. The design height is more than 1.5 meters, plus the length of the hanging handle, the length of each bag body is more than 2 meters, so the quality of the base fabric is the key. Although this kind of bag is not suitable for routine operations, its characteristics of one-hand grip and single lifting lug have become the biggest advantages of automatic filling. Now some large mining and chemical factories in Europe and the United States are introducing this filling equipment, which greatly liberates Manual labor, increasing the level of automation.

Grab the container bag, it should be a relatively alternative type of container bag. Its bag body is generally made of cylindrical cloth material, and there is no sling in the usual sense. The sling is a whole piece of base cloth connected to the main body. It is stitched with lap joints, a bit like a convenience bag used in supermarkets. The bag of this structure has higher requirements on the quality of the base fabric. First, the base fabric is used to replace the sling, which itself has higher requirements on the strength of the base fabric. Secondly, this kind of bag is not suitable for stacking storage. The design height is more than 1.5 meters, plus the length of the hanging handle, the length of each bag body is more than 2 meters, so the quality of the base fabric is the key. Although this kind of bag is not suitable for routine operations, its characteristics of one-hand grip and single lifting lug have become the biggest advantages of automatic filling. Now some large mining and chemical factories in Europe and the United States are introducing this filling equipment, which greatly liberates Manual labor, increasing the level of automation.

In today’s container bag industry, the technology is more and more professional, the quality is more and more mature, and it has more mature experience tailored for users.

Post time: Mar-04-2022